Nitrogénművek Zrt timeline

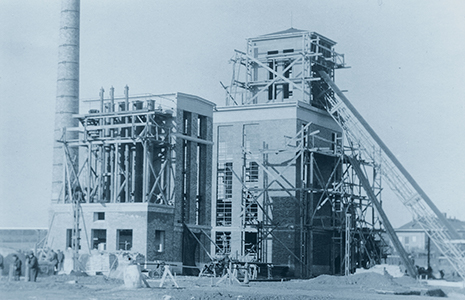

1931

Magyar Ammóniagyár Rt. in Pétfürdő and Magyar Műtrágyagyár Rt. in Pét are founded.

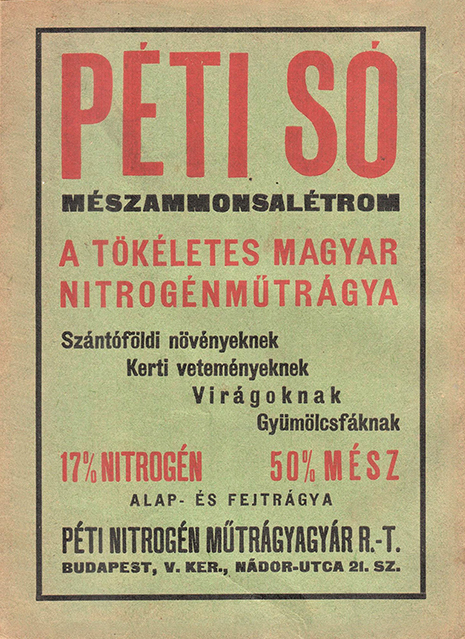

1932

Production starts in two factories and, on 28 June 1932, the most important product of the factory, Pétisó, is patented.

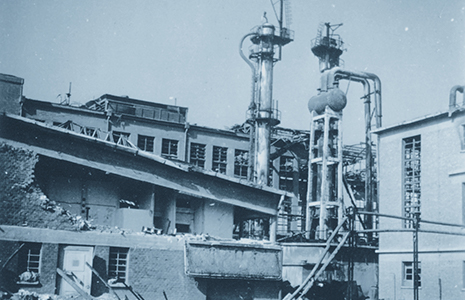

1944

In July, the ammonia plant and the fertiliser factory are completely destroyed and all factory units are severely damaged during bombing by Allied Forces.

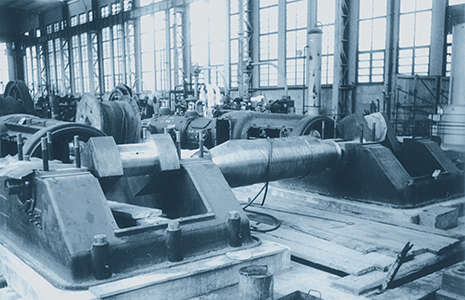

1948

Reconstruction work is completed and production reaches its pre-war peak.

1961

The company sets up a research laboratory to continuously test the quality of fertiliser products and carry out product development.

1964

Sees the switch to modern natural gas-based fertiliser production, which began with the Hungarian chemical industry’s first investment in a computer-optimised ammonia plant.

1964-71

Further developments include the start of production of a new dilute nitric acid plant, an expanded pétisó plant, a new urea plant, a lime water softener, an old ammonia plant modernised with atmospheric natural gas decomposition, an isopropyl amine plant and a dual fertiliser plant.

1972-75

The new high-capacity fertiliser plant is built using world-class technology. As part of that, an ammonia plant (1,000 t/day), a nitric acid plant (1,455 t/day), a urea plant (600 t/day) and a complex fertilizer plant (NPK 1:1:1 1,510 t/day, 25% N lime ammonium nitrate 1,150 t/day) are built. 2x26 km length water pipes, a 1,500 m3/hour capacity lime water softening plant, an ion exchange desalination plant with a capacity of 500 m3/hour, a desalination plant with a capacity of 100 m3/hour, six cooling towers, a boiler house, pipeline and railway network for the daily movement of 1,000 wagons are also established.

1975

Production of 34% ammonium nitrate begins.

1980-89

Construction of a combined nitric acid plant, a new argon plant and a new wastewater treatment plant.

1990

On 1 February 1990, Nitrogénművek Részvénytársaság is established.

1994

Péti Polietilén Zsák Kft. is established to meet the Company's needs in the production of packaging materials.

2002

Nitrogénművek Zrt. is established by the new owners, László Tibor Bige and Zoltán József Bige.

2003

The Bige Group consolidates its product range under the brand name Genesis. Nitrogénművek Zrt. joins the European Fertilizer Manufacturers Association (EFMA).

2004

The company acquires the plant for the production and distribution of liquid and suspension fertilisers in Nádudvar.

A national network of consultants is established and the sale of NPK products is launched. A national network of consultants is established and the sale of NPK products is launched.

2007

The nitric acid plant with a capacity of 1,650 t/day is inaugurated from an investment of HUF 30.8 billion. A state-of-the-art automated packing plant for unit loads and big-bags begins operation. A pneumatic powder conveying system is installed in connection with the new granulation plant, to convey the excess dolomite powder to the Pétisó plant.

2008

A granulation plant with a capacity of 1,100 t/day of granulated ammonium nitrate or 1,400 t/day of granulated pétisó is built. The new dolomite crushing system supplied by France is an integral part of the investment. Nitrogénművek Zrt. joined the Hungarian Innovation Club in 2008.

2010

Capacity increases are achieved by modifying the structure of the acid plant boiler (up to 1,800 t/day) and by modifying the internal part of the ammonia converter. The Genesis brand image and product packaging are renewed.

2011

A EUR 50 million bond is issued.

2012

The Genezis 2.0 conference series is launched, giving young farmers the opportunity to participate in presentations and programmes closely linked to the industry.

2013

A USD 200 million bond is issued to support growth plans. The Pétisó factory spray tower is upgraded, with 4 new extraction fans.

2014

The new dolomite crusher investment project is delivered. The Seed and the Crop Trade business are launched.

2015

Capacity expansion in the argon plant, with the installation of a new methane compressor with a capacity of 2,000 Nm3/h. A new packing building and big-bag packing equipment are installed in connection with the new granulation plant. The new neutralisation (S3) plant is inaugurated. The operation of the dolomite crusher (D2) begins. The modernisation and capacity expansion of the nitric acid plant from 1,650 t/day to 1,800 t/day is completed. The Genesis Pesticides business is launched. Start of own production of cereal crop seeds. The subsidiary Nitropet Croatia d.o.o. is established in Osijek.

2016

The investment cost amounts to HUF 34.7 billion. Expansion of the ammonia plant from a capacity of 1,200 t/day to 1,400 t/day. The new granulation (G2) plant is commissioned, one of the largest fertiliser plants in the world using the ‘pugmill’ granulation technology. The Siemens steam turbine-generator-turbomachinery group is activated, together with a new electrical network to generate electricity by utilising the high pressure and high temperature surplus steam produced by the technology. Granulation plant 2, producing 1,960 t/day of Pétisó or 1,550 t/day of granulated fertiliser of the ammonium nitrate type, is opened.

2017

The investment cost amounts to HUF 12.6 billion. Construction and commissioning of neutraliser 3 as part of the granulation plant 2. A new acid plant with a capacity of 1,150 t/day is built. That made the production of nitric acid at the Pétfürdő plant the highest in the region. The capacity expansion and reconstruction of the Pétisó plant to 1,800 t/day is completed.

The new dolomite grinding mill is inaugurated.

2018

The Company issues a bond of EUR 200 million, from which the USD 200 million bond was repaid. The new dolomite crushing plant 3 plant is opened.

2019

Online sales are launched as a new sales channel, via the genezisepartner.hu webshop.

2021

Nitrogénművek works with the European Bank for Reconstruction and Development (EBRD) to increase the energy efficiency of ammonia production in Pét and investigates how to integrate the production of ‘green’ ammonia into the existing production process, using renewable energy. The planned investment includes a 200 MW peak capacity solar farm and a 45 MW peak capacity wind farm, together with 400 MWh of storage capacity to ensure optimal energy use.

With expanded capacity, we now supply fertilisers to 16 countries.

2022

The logos will be harmonised in order to rebrand the Genesis brand at regional level. Consolidation of the company names of foreign subsidiaries and interests under the name Genezis Trade.

English (UK)

English (UK)